Northern Tunnel Portal changes in Minor Refinements Consultation

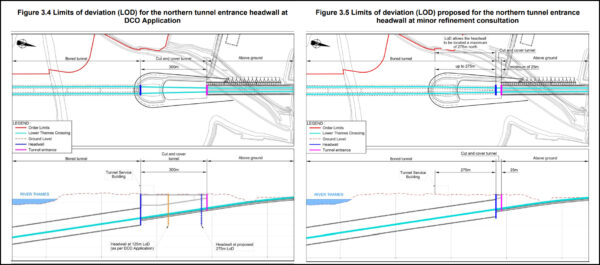

The Minor Refinements Consultation booklet refers to changes relating to an increase in limits of deviation (LOD) for the northern tunnel entrance headwall, but what does this really mean? Put very basically NH/LTC are saying they want some northern tunnel portal changes that would allow the constructors a bit more leeway in how they construct the northern tunnel entrance.

Why they have only now decided they may need this leeway is not made clear, and is something we’ve asked about.

When you build a tunnel a huge Tunnel Boring Machine is used. NH/LTC haven’t yet made up their mind whether one or two Tunnel Boring Machines would be used for LTC. More on that in our Tunnel Boring Machines update.

Ultimately it seems the decision on how many Tunnel Boring Machines would be up to the contractor, if the LTC goes ahead. It would also be up to the contractor exactly how the entrance would be constructed.

Currently, the DCO application documents state that the tunnel entrance would be made up of a section of tunnelled tunnel, and a section of cut and cover ‘tunnelling’.

Tunnelling is when the Tunnel Boring Machine is used, which inserts concrete tunnel sections as it bores through the ground.

Cut and Cover is when they dig the ground out, put concreate tunnel sections in place, and then cover them back up with soil etc.

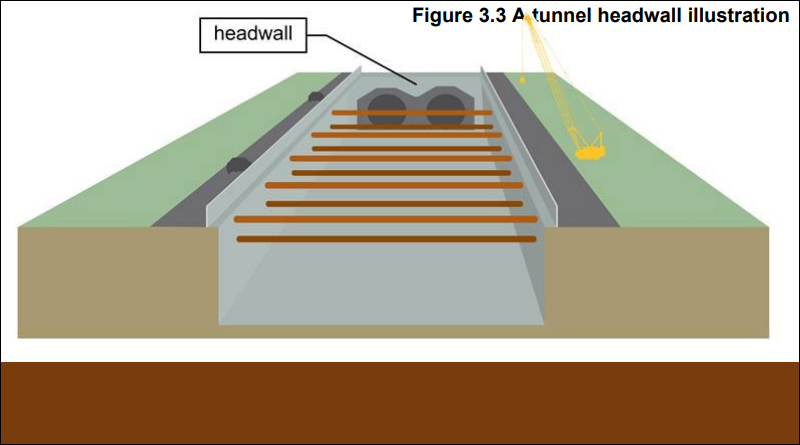

The point where the tunnelling begins has to have what is known as a Headwall. This is a reinforced concrete wall with holes in which the Tunnel Boring Machine starts boring through for the tunnelling. It is the point where the bored tunnel and cut and cover sections meet.

So when you’re going through the tunnel you would be in bored tunnel, you wouldn’t notice but technically you’d pass through the headwall, and into the cut and cover section of the tunnel, before coming out of the tunnel back into the open air.

So what’s the proposed change?

What is proposed is that the contractors could have up to an extra 125 meters of leeway for where they place the headwall to join the tunnel and cut and cover sections.

The actual position/location of where the tunnel would start/stop with the ‘outside world’ would remain in the same place. The change is all about how the tunnel was constructed either being bored with a Tunnel Boring Machine, or created using Cut and Cover.

The images below are taken from pages 14 and 15 of the consultation booklet (pdf pages 18/43 and 19.43. (click to enlarge)

To be clear the length of the tunnel does not change in length or position, just how it is physically constructed.

NH/LTC do state that there would be a minor reduction in material use associated with the change. Also that there would be a minor reduction in construction waste generated and material excavated during construction. However, they do not explain how much or why.

It is also mentioned in the consultation booklet that the change will have a negligible effect on resilience of the project to climate change, and on the amount of carbon emissions generated in the construction phase. However, again they do not explain what or how much.

The change relates to the northern tunnel portal, but since NH/LTC have also provided an update on the fact that one Tunnel Boring Machine (TBM) may be used instead of two, which would result in the second tunnel being bored from the south through to the north we are asking whether any change would be needed in a similar way for the southern tunnel portal.

Questions we put to NH/LTC on this change

Below are some questions we put to NH/LTC in regard to this proposed change after reading the consultation booklet, along with their responses:

Q1. Why has it taken until now for NH to decide the contractors may need extra leeway on the ratio of bored tunnel to cut and cover in the northern tunnel portal entrance?

“The Project continues to develop its design as a collaborative and iterative process, as explained in the Environmental Statement Chapter 2 – Project Description [APP-140]. The location of the headwall and the existing limits of deviation were derived from ground investigation data available at the time of the assessment. The proposed increase to the existing limits of deviation, provides the Delivery Partner with a greater flexibility in determining the most appropriate location for the headwall based on their additional ground investigation and detailed design. As detailed in the consultation materials, this greater flexibility does not introduce any materially new or different significant environmental effects.“

Q2. This change is all referring to the Northern Tunnel entrance, what about the southern tunnel entrance, will that need changes as well? If so why have they not been included in this consultation? If not, why not? Particularly since you also mention the possibility of only using one Tunnel Boring Machine, and turning it round and tunnelling back from the south to the north side.

“The proposed increase to the limits of deviation provides increased flexibility in determining the appropriate location for the headwall once further ground investigations have been undertaken by the Delivery Partner as part of detailed design for the northern tunnel portal. The southern tunnel entrance already has a limit of deviation that is deemed sufficient due to ground conditions and no further flexibility is required. The 1 TBM tunnelling methodology is not connected to the proposed limit of deviation change and has no impact on the southern portal.“

Q3. Please can you provide further details of how much of a reduction in material use associated with this change would be, and what it would be, why is there a reduction due to this change?

“The reduction in material use is wholly dependent on where the Delivery Partner determines is the appropriate location for the headwall, which is the transition point between the bored tunnel and the cut and cover structure. This will be determined during their detailed design. The potential for a reduction in material use relates to the length of the cut and cover structure and associated volume of material excavated for the cut and cover structure.”

Q4. Please can you provide further details of how much of a reduction in construction waste there would be, what it would be and why?

“The Delivery Partner’s detailed design will determine where the most appropriate location for the headwall is and will thus determine the associated elements of material use and construction waste generation. “

Q5. What is the effect that this change would have in regard to resilience of the project to climate change, please provide more details.

“There is no connection between the proposed increase to the limits of deviation and resilience for climate change. The headwall location is an internal interface between the bored tunnel and the cut and cover structure.”

Q6. What effect does this change have on carbon emissions, and how has this been calculated?

“As shown in Figure 3.3 of the Minor refinement consultation guide, the tunnel headwall represents the transition between the bored tunnel and the cut and cover structure. Any increase to the length of the bored tunnel comes with a matching decrease in the cut and cover structure. The carbon assessment within the DCO Application represents a reasonable worst case assessment. As stated in the environmental assessment provided with the Consultation materials, the increase in the Limits of Deviation for the headwall will have a negligible effect on the amount of carbon generated in the construction phase of the Project.”

We do not feel that NH/LTC have adequately answered some of our questions, but very much doubt we will receive any further responses before the consultation ends.

Related

LTC Tunnel – click here